- Products

- Support & Download

- Solutions

- Contacts

- About Brother

SPEEDIO

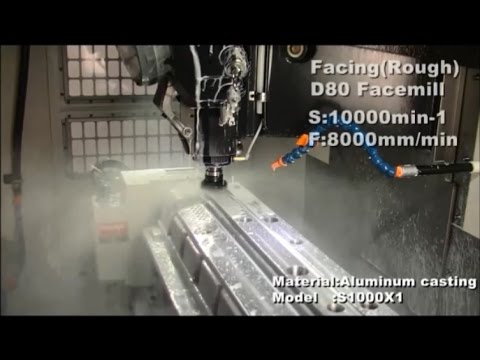

S1000X1

"Machining larger workpieces using #30 machine"

The release of the S1000X1 machining center sees an override in the conventional machining areas of #30 machines.

Continuing in the spirit of overwhelming high productivity,

the machine will launch a challenge to new machining areas,

boosting our "Brother also in this process" concept.

Product points

Machining Area

Increase in X- and Y-axes travels and expansion of the machining area have enabled large workpiece machining and large jig mounting, which were not possible on conventional #30 machines.

Productivity

Compared to a machining center with the same machining area, Brother's original high-speed and optimal operation control results in overwhelming high productivity.

High reliability

Chip discharge performance has been improved along with the expansion of the machining area. In addition, the machine is equipped with a variety of functions, such as air-assisted tool washing, to improve reliability.

High environmental performance

In addition to low power and air consumption, the machine is equipped with a power regeneration system and a variety of energy saving functions, achieving high environmental performance.

Specifications

| item | S1000X1 |

|---|---|

| Max. spindle speed | 10,000min-1 10,000min-1 high-torque(Optional) 16,000min-1 (Optional) |

| Travels | X:1,000mm Y:500mm Z:300mm |

| Tool storage capacity | 14pcs./21pcs. |

| Rapid traverse rate (XYZ-area) | 50m/min × 50m/min × 56m/min |

| Required floor space | 2,410mm × 2,442mm |

| BT dual contact spindle (BIG-PLUS) | Optional |

| Coolant Through Spindle (CTS) | Optional |

Product movie

Machining example

For machining industries in Automotive parts, Motor cycle parts, Information Technology parts.

Customer considering purchase / Support Information

-

Catalog download

Guide of Compact machining center SPEEDIO catalog download.

-

Distributors - Inquiry & Purchase , Repair & Service

Contact information for distributors in your area.

-

Brother Technology Center

Contact information for Brother Technical Centers in Europe and other areas.